3D printers have been available in the home market for many years, with the range of models increasing over time and the costs reducing. Historically, 3D printers have built a reputation of being complex and uncommon, most needing significant assembly before use. This has been challenged recently with new companies entering the market claiming low set-up times and easy to use devices. For this issue we look at how useful and accessible home 3D printers now are, especially for ophthalmic professionals.

Types of 3D printing technology

Filament printing is the main technology used in home 3D printers. Resin printing is another option, ideal for creating small and detailed models, like gaming miniatures. Resin printers require the handling of messy and toxic liquids and consequently are not a good choice for those new to 3D printing. Consequently, for the rest of the article we will focus on filament (also known as FDM) printing.

The word ‘filament’ describes the roll of (typically coloured) plastic that is fed into the machine and used to print. It is akin to the glue sticks that push into hot glue guns. The glue gun comparison can be taken further as filament printers are, at a simplified level, rapidly moving hot glue guns that build models from the ground up, layer by layer. The nozzle is heated to a temperature between 200-240°C and is precisely moved around the model, depositing small amounts of the plastic filament before moving up a layer. A typical model is built up from layers of 0.2mm thick.

Materials

The most common type of plastic is PLA, which is a polymer of lactic acid (Polylactic Acid). The main source of the lactic acid is from the fermentation of corn starch. PLA is available in a wide range of coloured filaments for 3D printing, with a kilogram roll typically costing £20-30. PLA is easy to print with, safe to handle and has good physical strength. Other materials are available with different properties.

The practicality of switching to a different colour filament (or material) during a print depends on the printer. Most devices print in a single colour but provide a way to pause the print to switch filament. This allows for a basic form of multi-colour printing. Some of the more expensive printers have multiple rolls and nozzles and can efficiently switch between them on the fly.

Sending a file to the printer

Different methods of sending files to printers exist, depending on model. Often a memory card or USB stick is used, but more recently printing over WiFi (or even a mobile app) is supported by some. Whether you create your own designs or download designs from the internet, the most common file type is an STL file. Although these files contain the structure and dimensions of the model, further processing is required before printing can be performed.

The model files need to be run through a ‘slicer’ to convert them into a code file that is then passed to the printer using one of the methods above. As printing occurs layer by layer, the slicing process is needed to turn the model into instructions specific to the printer, the material chosen and the speed of printing among other configurable variables. It is worth noting that while a small model may only take 10-20 minutes to print, a large model printed on a modern fast printer can easily take over 12 hours to complete.

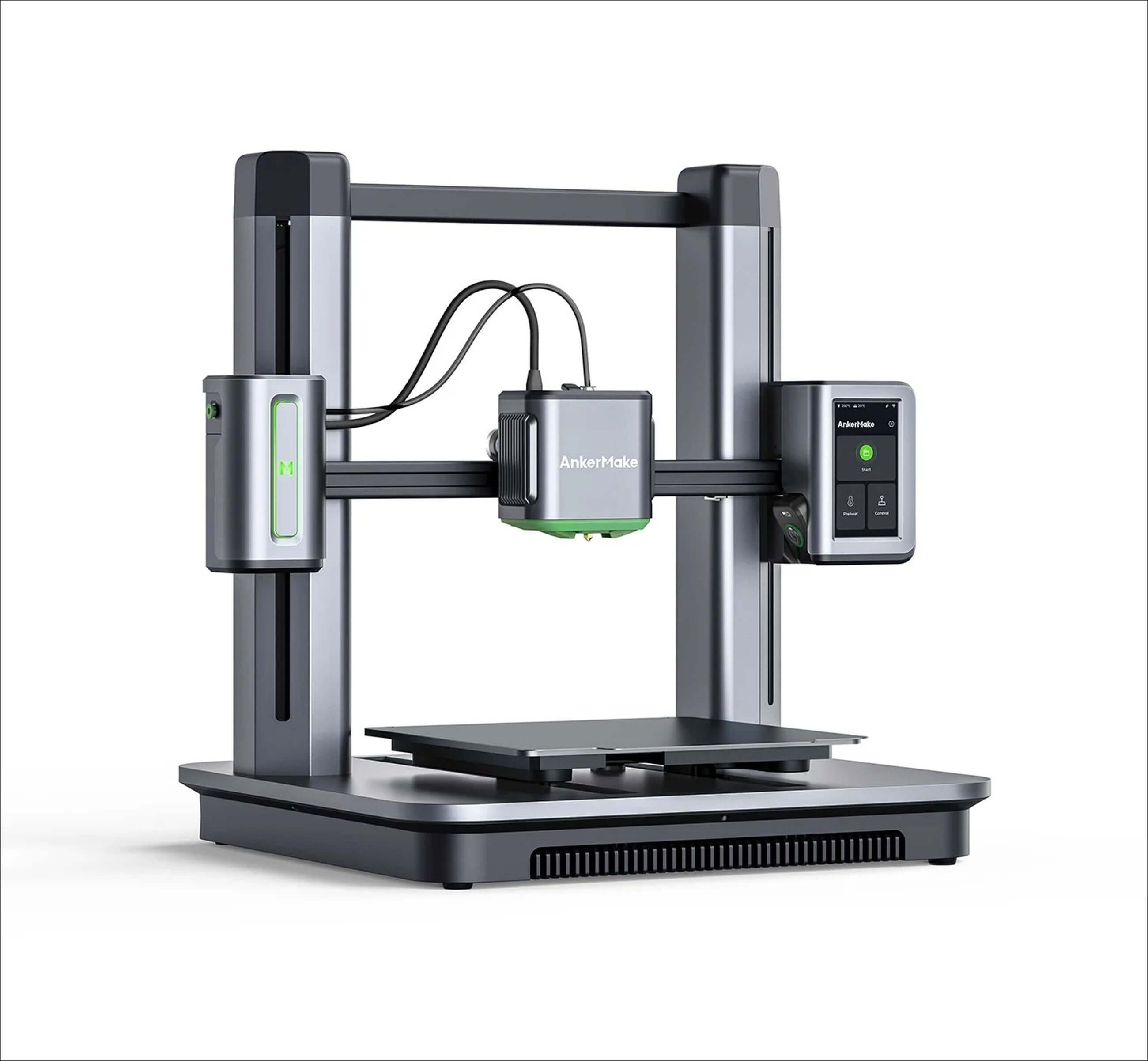

Figure 1: Ankermake M5.

Printer suggestions

Reviewing or making recommendations of specific models of 3D printers is beyond the scope of this article. I only have personal experience of the model I own, The Ankermake M5, shown in Figure 1. That printer did prove easy to assemble and start printing with. Many sites do offer full reviews and recommendations, such as this one from Techradar: www.techradar.com/best/best-3d-printers. As far as cost is concerned, an entry level printer can be purchased for around £300. Spending more than double that is easily possible, with print size and capabilities of the devices increasing accordingly.

Creating models vs. downloading

One of the most amazing aspects of having access to a 3D printer is designing and printing your own models. This does take some time if you are new to 3D printing. I found it best to learn how to print downloaded models first before working on my own. Time and effort were certainly required, but nothing too difficult and plenty of free online guides are available. Modelling software is needed to make your own designs, but several free options exist:

- Tinkercad (www.tinkercad.com) is free but basic.

- Fusion 3D (www.autodesk.co.uk/products/fusion-360/personal) and

- OnShape (www.onshape.com/en/products/free) are more powerful and fully featured. Both offer free tiers that are sufficient to the novice home user.

Online archives of models

Several websites have large archives of freely downloadable models. Paid archives also exist, and some creators sell their designs via private sites. The main sites to start with are Printables, Thingiverse, Thangs and Cults3d. Those and more can easily be found from a simple internet search.

Examples of freely available ophthalmic designs

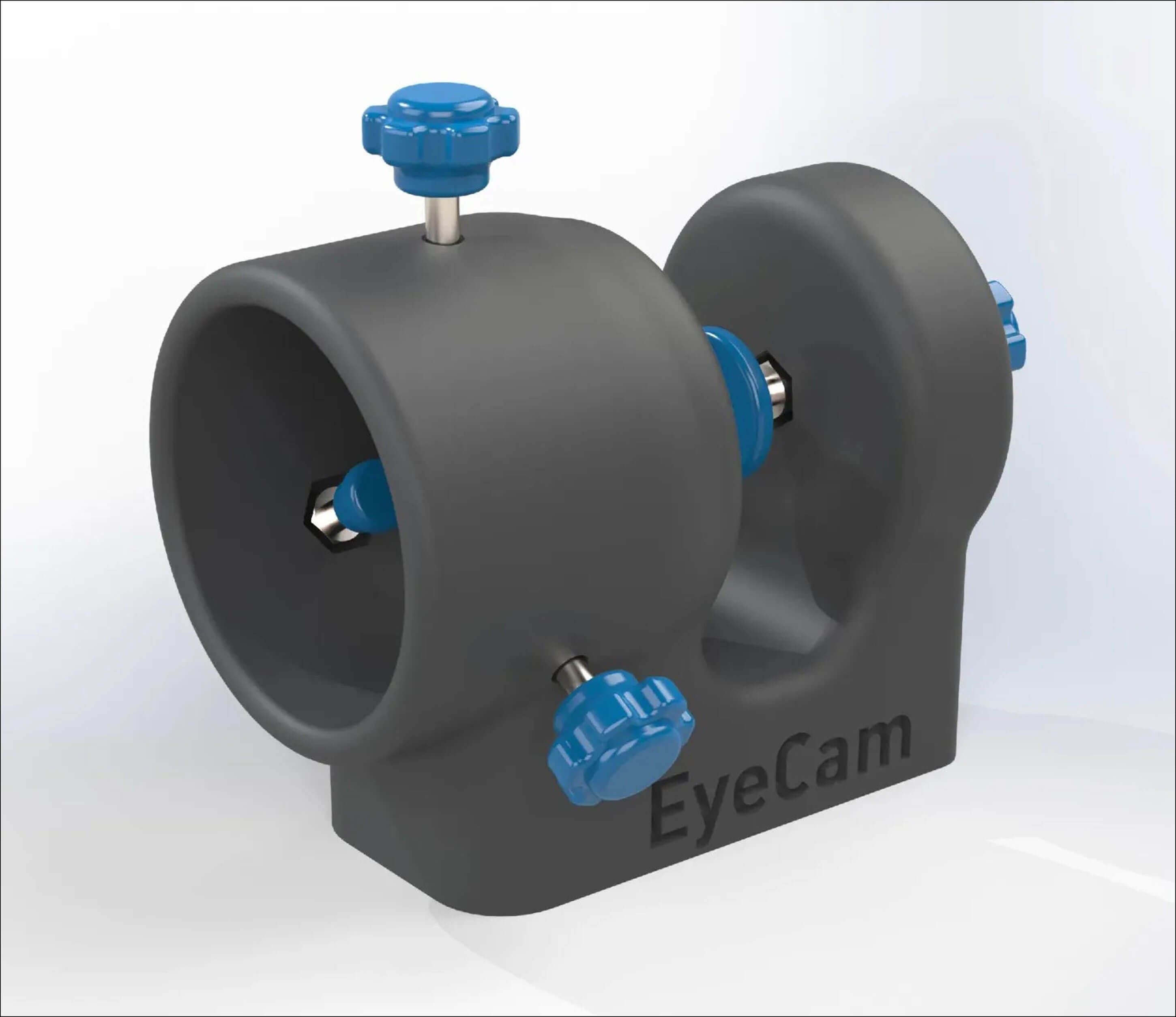

A good way to see what designs are available is to search for ‘ophthalmology’ and ‘eye’ on Printables or Thingiverse. Figure 2 shows a free to download and print phone to slit-lamp adaptor (search for ‘Eyecam’ on Printables). There are a range of Volk lens boxes, occluders, eye models and more freely available.

Figure 2: A free phone to slit-lamp adaptor.

As a final example of a user-created model, Figure 3 shows one I created myself and have made freely available on Printables (tinyurl.com/3dclinic). The model is a form of desktop organiser for when I am in my glaucoma clinic. It includes recesses for a torch, gonioscopy lens, lens lubricant, lidocaine / fluorescein vials, loaded applanation prisms, a phone and an area for spent prisms and vials. I load it up at the start of my clinic, while I am waiting for my first patient, and it helps reduce wasted time between patients as my refills are already prepared.

Figure 3: My own clinic organiser design.

Summary

Home 3D printing is accessible and certainly rewarding from a creative perspective. The investment in time and energy is significant and not at all as straightforward as printing on a typical paper printer. However, with a little patience and effort one can quickly create a prototype (or fully usable) model from an idea. The technology is mature and certainly has utility for interested ophthalmic professionals, possibly more as an aside than as a primary reason to invest in 3D printing.

Declaration of competing interests: None declared.

The author has no proprietary or financial interests in the products discussed.

COMMENTS ARE WELCOME