Ongoing technological developments are enabling continuous progress to be made across all aspects of medical simulation training. This is particularly true within the field of ophthalmology, where surgical training advancements have enabled the role of simulation to expand dramatically over recent years.

This makes ophthalmic surgical training safer for both the patient and the trainee. Simulation exposure is now an essential component of the Royal College of Ophthalmologists’ Ophthalmic Specialist Training curriculum prior to real-life surgery. Bespoke intraocular simulation using the computerised EYESI simulator for cataract (and vitreoretinal training) is now supplemented with realistic model eyes to ensure trainees are well rehearsed and further along the learning curve, which has corresponded with a reduction in surgical complication rates.

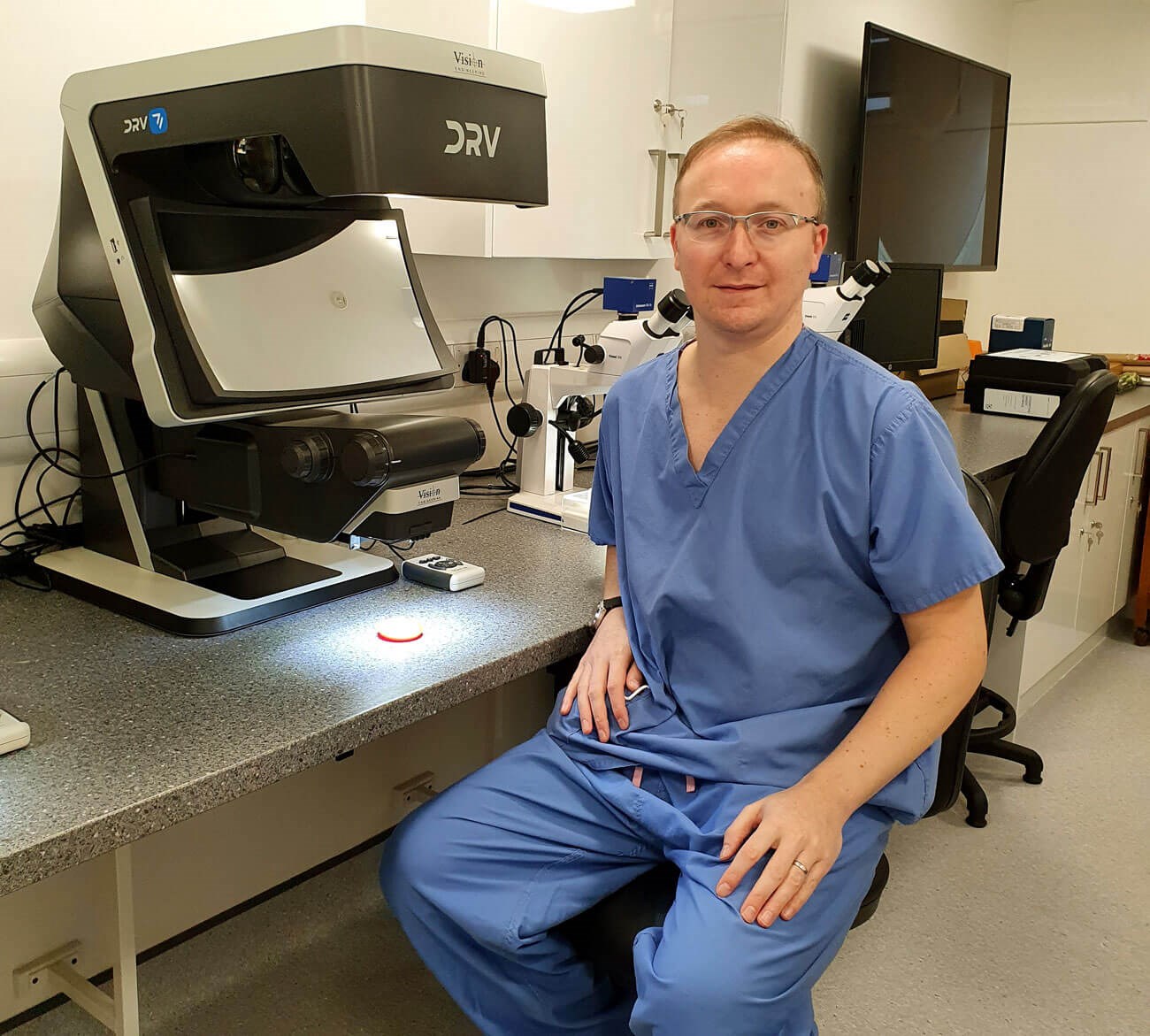

As a keen advocate of “simulation for safer surgical training”, Dr David Lockington (Consultant Ophthalmologist; National Simulation Lead for the Royal College of Ophthalmologists) recently renovated to innovate a modern bespoke ophthalmic surgical simulation suite within the Tennent Institute of Ophthalmology in Glasgow. This “Teach and Train” hub provides all the resources required to ensure trainees can develop surgical skills and refine their techniques for better patient outcomes.

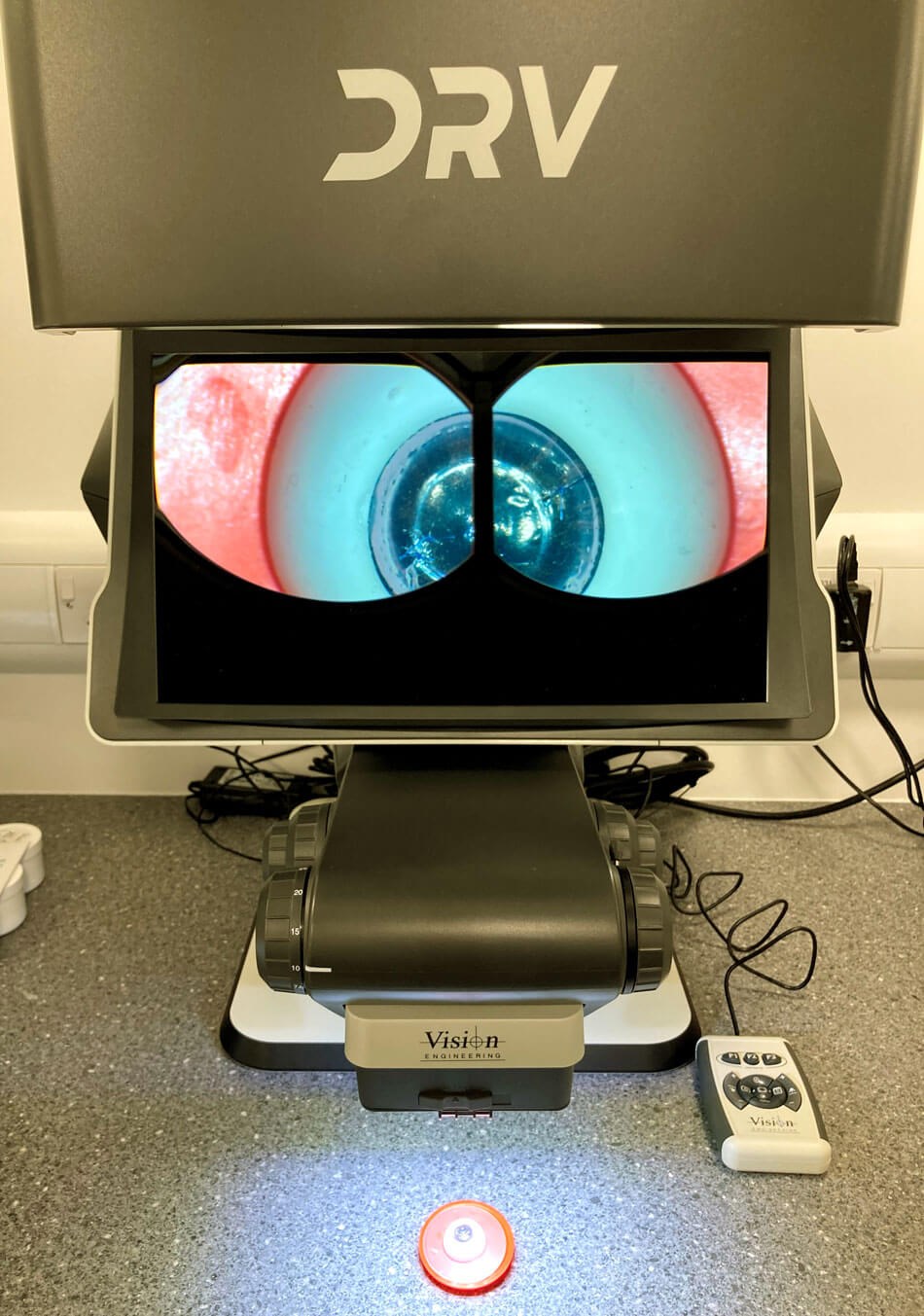

Amongst the advanced simulation technologies and training aids installed in the Tennent Institute of Ophthalmology surgical simulation suite is a recently launched DRV-Z1 (Deep Reality Viewer). Designed and manufactured by UK company Vision Engineering Ltd, the revolutionary DRV-Z1 is the world’s first glasses-free digital stereo inspection system which creates precise, full 3D HD images that ‘float’ in front of the user’s eyes. The remarkable invention is now revolutionising medical training techniques and changing the way organisations capture, view and share 3D images.

Through the use of the DRV-Z1 trainees in the Glasgow-based surgical simulation suite are reaping the dual benefits of optical stereo microscopy and advanced digital technology in a single system. The DRV-Z1 provides impressive levels of simulation by delivering fully immersive 3D visualisations with outstanding perception of depth, and magnifications of between 6.1x and 186x with zoom capabilities.

Whilst the intelligent design makes it possible to output mono images to TV or computer screens for audience viewing, the DRV-Z1 represents the ideal collaborative teaching aid as its high-definition 3D images can be shared in real time between tutors and trainees. Also, simultaneous remote viewing can be achieved across remote networks with other DRV systems. Further aiding effective training, these captured 3D images and videos can be recorded, archived and later reviewed.

Thanks to the unit’s ergonomic design, the eye strain, posture problems and fatigue issues associated with extended hours of viewing conventional optical stereo microscopes are eliminated. Now, users are able to sit in their preferred comfortable positions to work ‘heads-up’. The DRV-Z1’s user-friendly design also enables easy hand-eye coordination when carrying out procedures such as dissections. Furthermore, there are no limitations for wearers of prescription spectacles, safety glasses or PPE.

Explaining the purchase and use of the DRV-Z1 in the Tennent Institute of Ophthalmology simulation suite in Glasgow, David Lockington said: “All trainee ophthalmologists have to complete mandatory virtual reality modules on the EYESI cataract simulator prior to live surgery. However, we wished to ensure they had further surgical exposure and so resourced our simulation suite with a wide range of model eyes to develop wound creation and corneal suturing skills. Furthermore, sub-specialty procedures for glaucoma, retina, cataract and corneal surgery can be rehearsed and refined to ensure competence and confidence within the safe and supportive environment of our dry-lab.”

“A major objective of our surgical simulation suite is to equip trainees for real surgery by using technologies that replicate actual clinical situations as closely as possible. Whilst searching for such equipment I came across the DRV-Z1. The full 3D HD images offer a clear advantage over traditional binocular eyepiece microscopes, with a better user experience due to the heads-up posture.

“Our trainees are now able to gain the advantage of performing surgical simulation tasks in a more ergonomic way, including viewing high magnification 3D images without the need for additional glasses. Vision Engineering’s DRV-Z1 has been an extremely valuable addition to our dry-lab and I believe that it represents an ideal technology for use in similar ophthalmology training simulation situations.”

Stewart Mardell, VP of the Vision TriTeQ Division of Vision Engineering Ltd, concluded: “We are delighted to be working with David with this development and are glad that all West of Scotland ophthalmologists can now benefit from state of the art display technology as they learn, develop, and refine their ophthalmic surgical skills in the Tennent Institute of Ophthalmology’s surgical simulation suite.

“Vision Engineering products are used by the medical fraternity, scientists, engineers and technicians across the globe. Vision Engineering Ltd, is a true British success story: From the company’s foundation in 1958, we have grown to become the world’s leading ergonomic microscopy company, designing and manufacturing high-quality microscopes, digital instruments, and inspection and non-contact measuring systems.

“Protected by world patents, our unique eyepiece-less optical technologies – which remove the need for conventional binocular microscope eyepieces – are changing the way people inspect and perform through industry-leading ergonomic design.“

COMMENTS ARE WELCOME